Waste Heat Recovery on Board Cruise Ships

Climate change caused by human activities is a well-established fact. According to the Fourth IMO Greenhouse Gas Study by the International Maritime Organization (IMO), shipping CO2 emissions account for just 2.89% of the global total.

Despite this relatively low percentage, the IMO is committed to reducing its environmental impact and has incorporated this goal into its Strategic Directions. Regarding greenhouse gas emissions, the IMO aims to cut shipping emissions by 40% by 2030, compared to 2008 levels. To achieve this, measures such as the Energy Efficiency Existing Ship Index (EEXI) and the annual operational Carbon Intensity Indicator (CII) have been implemented.

Onboard activities, including propulsion, air conditioning, and hospitality services, contribute significantly to energy consumption on cruise ships. With a growing emphasis on sustainability and environmental responsibility, the cruise industry is exploring innovative technologies to improve energy efficiency and reduce greenhouse gas emissions. One such technology is waste heat recovery (WHR), a process that captures and repurposes excess heat generated by the ship’s engines and other systems. This essay delves into the principles of WHR, its implementation on cruise ships, and the significant improvements in efficiency and sustainability it offers.

CLIMEON HeatPower 300 Marine System

Principles of Waste Heat Recovery

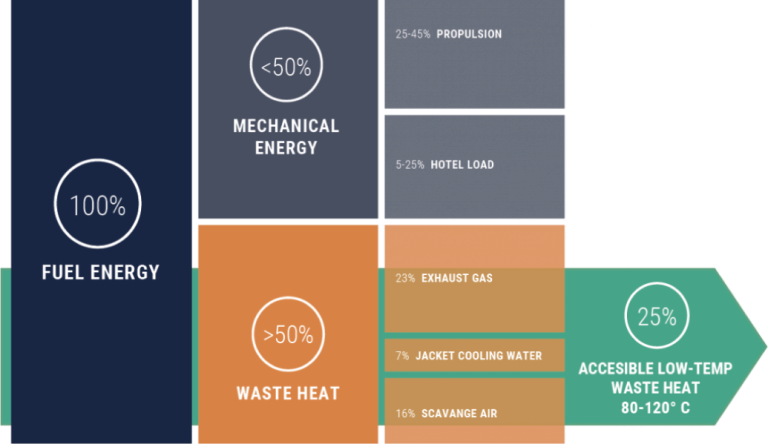

Waste heat recovery on cruise ships is pivotal for harnessing heat that would otherwise dissipate into the environment and converting it into valuable energy. Key sources of waste heat onboard are essentially the diesel generators. WHR systems utilize technologies such as heat exchangers, exhaust gas boilers, and systems for utilizing waste steam to capture and convert this heat into electricity or thermal energy for diverse onboard applications. In addition to these components, absorption chillers play a significant role in WHR systems by utilizing waste heat for cooling purposes. Absorption chillers absorb refrigerant vapor into an absorbent solution, driven by the waste heat from engines or other sources. This process generates chilled water that can be circulated through the ship’s HVAC system, enhancing cooling efficiency and reducing the load on conventional cooling systems. Furthermore, high and low-temperature circuits are essential for efficient energy management onboard. High-temperature circuits manage heat from sources like engine exhausts and cooling systems, which can be used to produce steam or hot water for various purposes. Low-temperature circuits handle less intense heat, typically employed in processes like refrigeration. Integrating these circuits effectively ensures that waste heat is maximized to improve overall energy efficiency and sustainability practices aboard cruise ships.

– Heat Exchangers:

Heat exchangers are vital components on board cruise ships, playing a crucial role in energy management and efficiency. These devices transfer heat between two or more fluids without mixing them, enabling the effective utilization of thermal energy generated by various shipboard systems. On cruise ships, heat exchangers are heavily used in multiple applications to enhance operational efficiency and sustainability.

One primary use of heat exchangers is in the ship’s engine cooling system. Here, they transfer heat from the engine coolant to seawater, preventing engine overheating and maintaining optimal performance. Additionally, heat exchangers are integral to the HVAC (heating, ventilation, and air conditioning) systems, where they manage the ship’s climate by transferring heat from the air conditioning system to the external environment or vice versa. Another critical application is in waste heat recovery systems. Heat exchangers capture excess heat from the ship’s exhaust gases and other high-temperature processes, which is then utilized to generate steam for electricity production or to heat water for onboard use. This process significantly reduces fuel consumption and lowers greenhouse gas emissions.

Furthermore, heat exchangers are used in desalination plants on cruise ships, where they help convert seawater into fresh water by recovering and reusing heat from the desalination process.

Overall, the extensive use of heat exchangers on cruise ships underscores their importance in improving energy efficiency, reducing operational costs, and minimizing the environmental impact of maritime operations.

– Exhaust gas:

Cruise ships employ exhaust gas boilers (EGBs) to harness waste heat from engine exhaust gases. Positioned strategically within the ship’s exhaust system, EGBs transfer high-temperature exhaust gases’ thermal energy to water circulating through tubes or pipes. EGB are positioned in the ship’s funnel or exhaust system, where they capture heat from the hot exhaust gases produced by the ship’s main and auxiliary engines. These gases can reach temperatures exceeding 500°C. This process generates steam, which serves multiple onboard purposes, especially to provide heated water for various amenities and processes onboard. By effectively utilizing waste heat, exhaust gas boilers enhance energy efficiency, lower operational costs, and contribute to sustainable maritime practices by minimizing greenhouse gas emissions.

– Steam waste:

Waste steam on board cruise ships, generated from engine exhausts and heating systems, can be harnessed for energy efficiency. The principle is to use waste steam, often a byproduct of engines exhaust gas boiler, typically contains significant thermal energy that would otherwise be lost. By implementing waste heat recovery systems like the Organic Rankine Cycle and steam turbines, this steam can be converted into electricity or used for heating, reducing fuel consumption and emissions while enhancing sustainability.

York Two-step Evaporator and Absorber

CLIMEON low temperature waste heat

The Organic Rankine Cycle (ORC)

ORC system is a thermodynamic process used to convert low-temperature heat sources into electricity. Named after the conventional Rankine cycle, the ORC system employs organic fluids with low boiling points, such as refrigerants or hydrocarbons, instead of water. This adaptation allows the ORC to efficiently harness heat from low-temperature sources like industrial waste heat, geothermal energy, biomass combustion, and solar thermal energy. The ORC process involves four main steps: evaporation, expansion, condensation, and pumping. The working fluid is first heated by the low-temperature heat source in the evaporator, causing it to vaporize. This high-pressure vapor then drives a turbine or an expander, generating electricity. After passing through the turbine, the vapor is condensed back into a liquid in the condenser and pumped back to the evaporator, completing the cycle. ORC systems are particularly advantageous due to their ability to utilize low-grade heat that would otherwise be wasted. They offer high efficiency and reliability, low maintenance requirements, and can be scaled to various sizes depending on the heat source. Their application spans across multiple industries, making them a versatile and sustainable solution for enhancing energy efficiency and reducing greenhouse gas emissions.

Steam turbines

Steam turbines that utilize waste steam are a crucial technology for improving energy efficiency and sustainability for cruise ships. Steam turbines capture the waste steam and convert its thermal energy into mechanical work, which is then used to generate electricity. The process begins with waste steam being directed into the turbine. As the steam passes through the turbine blades, it causes them to spin. This rotational motion drives a generator, producing electricity. By using waste steam, these turbines effectively recover energy that would otherwise be wasted, enhancing overall energy efficiency.

Additionally, the use of steam turbines for waste steam recovery aligns with environmental regulations and sustainability goals. It helps the maritime industry minimize its carbon footprint, contributing to cleaner and more sustainable operations. Overall, steam turbines that utilize waste steam represent a vital step towards more efficient and eco-friendly energy use in the maritime sector. In the context of cruise ships, integrating steam turbines with waste heat recovery systems can significantly reduce fuel consumption and greenhouse gas emissions, although limited space on board existing cruise ships is a huge challenge and also the additional weight of a steam turbine system can impact as it cannot be installed everywhere on board.

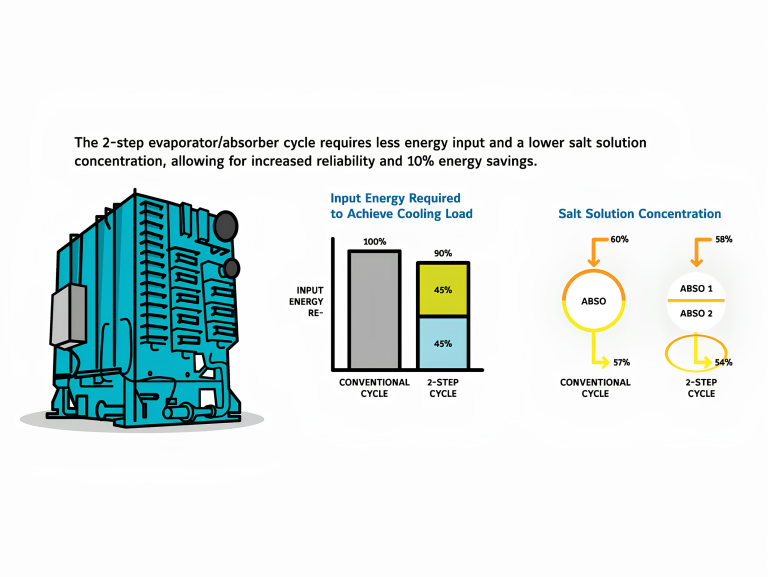

Absorption Chillers

Absorption chillers are seamlessly integrated into cruise ships as chiller water boosters to augment the cooling capacity of the HVAC (Heating, Ventilation, and Air Conditioning) system. They utilize waste heat sourced from engine exhausts or other heat-generating processes onboard. This waste heat is pivotal for driving the absorption cycle of the chiller. In operation, absorption chillers facilitate the absorption of refrigerant vapor into an absorbent solution, typically lithium bromide. As the refrigerant vaporizes and condenses back into a liquid, it generates chilled water. This chilled water is then fed into the ship’s chilled water distribution network, supplementing the cooling load of the HVAC system.

Usually, they are integrated as chiller water boosters offering several benefits as they enhance the overall cooling capacity of the vessel, ensuring that peak cooling demands can be met efficiently. By utilizing waste heat for cooling, absorption chillers contribute to improved energy efficiency and reduced fuel consumption compared to conventional compression chillers that rely solely on electrical power. This integration enhances operational flexibility, allowing cruise ships to optimize cooling operations while minimizing environmental impact and operational costs. Ultimately, absorption chillers play a crucial role in supporting sustainable practices onboard cruise ships, providing comfortable environments for passengers and crew alike.

High and low temperatures circuits:

Cruise ships rely on both high-temperature and low-temperature circuits to effectively manage thermal energy for diverse operational needs. High-temperature circuits primarily involve diesel generators to provide, capture and transfer excess heat from engine cooling systems hot water for various onboard applications. Conversely, low-temperature circuits play a critical role in maintaining optimal cooling and air conditioning throughout the vessel. They manage refrigeration systems essential for storing perishable goods and supplies at low temperatures. Moreover, these circuits are integral to the ship’s HVAC infrastructure, ensuring comfortable indoor environments for passengers and crew alike.

These systems are used, for example, for fresh potable water pre-heating and pool water heating onboard. High-temperature circuits, harness waste heat from engines to heat potable water meanwhile, low-temperature circuits manage (often) pool water heating, employing dedicated systems connected to the ship’s HVAC infrastructure. This dual approach ensures that passengers enjoy hot water and comfortably heated pool facilities, all while optimizing energy use and minimizing environmental impact. The integration of high and low-temperature circuits is facilitated through sophisticated heat exchange processes and control systems. This integration optimizes overall energy efficiency by recycling waste heat and minimizing energy consumption across different operational systems. By effectively utilizing both types of circuits, cruise ships enhance their sustainability efforts, reduce fuel dependency, lower greenhouse gas emissions, and achieve significant operational cost savings over time. This comprehensive approach underscores the maritime industry’s commitment to environmental responsibility while delivering a comfortable and efficient cruising experience.

Implementation onboard

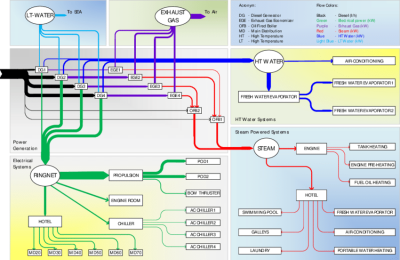

Implementing Waste Heat Recovery (WHR) systems on cruise ships demands meticulous planning and seamless integration with current infrastructure. This process begins with identifying and quantifying waste heat sources onboard, such as engine exhausts and cooling systems. The next critical step involves designing a WHR system that aligns with the ship’s unique operational demands, selecting appropriate components like heat exchangers, boilers, and turbines. Integration with existing power generation and distribution systems is crucial to ensure smooth operation. Furthermore, continuous monitoring systems are implemented to track the WHR system’s performance and fine-tune efficiency over time. This comprehensive approach not only maximizes energy recovery but also enhances overall operational sustainability, reducing fuel consumption and emissions while maintaining reliable onboard services for passengers.

Several cruise lines have already begun to implement WHR systems on their vessels. For instance, companies like Royal Caribbean and Carnival Corporation have equipped some of their newer ships with advanced WHR systems, achieving notable reductions in fuel consumption and emissions.

Alfalaval E-PowerPack

York YHAU-C Single Effect Steam Absorption Chille

Efficiency Improvements

Waste Heat Recovery (WHR) systems represent a significant technological advancement in enhancing energy efficiency aboard cruise ships. These systems are designed to capture and utilize waste heat originating from various onboard sources such as engine exhausts and auxiliary systems. By effectively harnessing this otherwise wasted thermal energy, WHR systems can achieve substantial fuel savings, typically ranging from 10% to 15% of total fuel consumption. These savings are contingent upon operational conditions and the efficiency of the WHR technology employed, which includes components like heat exchangers, exhaust gas boilers, and systems for utilizing waste steam.

From an engineering perspective, WHR systems contribute to reducing greenhouse gas emissions such as CO2, NOx, and SOx. This reduction is critical for complying with stringent international environmental regulations set forth by organizations. The electricity generated from recovered waste heat not only offsets the power demands of the ship but also enhances the overall onboard power capacity. This supplementary electrical power reduces the load on primary generators, thereby optimizing their efficiency and prolonging their operational life. Moreover, WHR systems play a crucial role in improving thermal management onboard cruise ships. They provide efficient heating solutions for HVAC systems and contribute to the supply of hot water throughout the vessel. This dual functionality not only ensures passenger comfort but also maximizes energy utilization efficiency.

In conclusion, the integration of WHR systems on cruise ships not only enhances operational efficiency and financial savings but also significantly reduces environmental impact. By minimizing fuel consumption and emissions while optimizing energy use, WHR systems underscore the cruise industry’s commitment to sustainability and the adoption of eco-friendly technologies. This approach not only benefits cruise operators by lowering operational costs but also promotes sustainable maritime practices, aligning with global efforts towards environmental stewardship in the shipping industry.

Beyond efficiency improvements, WHR systems significantly enhance the sustainability profile of cruise ships. The cruise industry is under increasing scrutiny for its environmental impact, and adopting WHR technology is a proactive step towards greener operations. By reducing fuel consumption and emissions, WHR systems help mitigate the environmental footprint of cruise ships, aligning with global efforts to combat climate change.

Moreover, the adoption of WHR technology sets a positive precedent for the broader maritime industry. As cruise lines demonstrate the viability and benefits of WHR systems, other sectors, such as cargo shipping and offshore operations, may be encouraged to adopt similar technologies, amplifying the environmental benefits across the maritime industry.

The-schematic-diagram-of-a-cruise-ship’s-main-energy-systems

Conclusion

Waste heat recovery (WHR) technologies are pivotal for enhancing sustainability and operational efficiency aboard cruise ships, encompassing advanced systems such as Organic Rankine Cycle (ORC) systems, heat exchangers, steam turbines, and absorption chillers. These systems collectively contribute to reducing fuel consumption, cutting emissions, and maintaining passenger comfort.

ORC systems exemplify cutting-edge waste heat recovery by converting low-grade waste heat—like that from engine exhausts or auxiliary systems—into electricity through a closed-loop cycle using organic fluids. This not only generates additional onboard power but also reduces reliance on conventional generators, optimizing fuel use and lowering greenhouse gas emissions. Heat exchangers play a crucial role by efficiently transferring heat between fluids without mixing them. On cruise ships, they capture waste heat from sources such as engine cooling systems and exhaust gases. This recovered heat can be used to preheat water for domestic use, support HVAC systems, or drive ORC systems for electricity generation, thereby enhancing overall energy efficiency across the vessel.

Complementing these efforts, steam turbines harness high-pressure steam generated from waste heat sources to drive onboard generators or propulsion systems. By converting thermal energy into mechanical power, steam turbines maximize the utilization of otherwise wasted heat, significantly reducing fuel consumption and operational costs. Meanwhile, absorption chillers utilize waste heat to facilitate cooling processes onboard. They efficiently produce chilled water using heat from exhaust gases or other sources, crucial for maintaining comfortable indoor temperatures for passengers and crew.

In conclusion, integrating these systems into waste heat recovery strategies on cruise ships represents a comprehensive approach to sustainability and efficiency. These technologies not only mitigate environmental impact but also enhance operational resilience and cost-effectiveness, ensuring cruise ships navigate towards a greener future while delivering exceptional onboard experiences.

Don’t miss more updates, news and reviews about the world of cruises on Cruising journal.