Waste management on cruise ships

Managing waste, including wastewater and food disposal, is a critical aspect of operating cruise ships sustainably and responsibly.

Waste Disposal

With thousands of passengers and crew members on board, cruise ships generate significant amounts of waste that must be properly handled to protect the marine environment and comply with regulations. From wastewater treatment to food waste management, cruise lines employ advanced technologies and practices to minimize their environmental footprint and ensure the health and safety of everyone on board. Waste disposal on board cruise ships is a crucial aspect of their operation, as they need to manage various types of waste generated by thousands of passengers and crew members. Effective management of solid waste on board cruise ships involves a combination of segregation, storage, compaction, and responsible disposal practices to minimize environmental impact and ensure compliance with regulations.

Cruise ships must comply with strict international and local regulations regarding waste disposal to protect the marine environment regulated by International Maritime Organization (IMO) regulations, such as MARPOL (International Convention for the Prevention of Pollution from Ships), set standards for waste management and disposal at sea.

Food Digester

General waste and recycling

Waste disposal on board cruise ships involves a combination of separation, storage, processing, and proper disposal methods to minimize environmental impact and comply with regulations. Cruise lines continually strive to improve waste management practices through innovation and technology.

Here’s a breakdown of how waste disposal typically works on cruise ships:

Solid waste on board ships encompasses a wide range of materials generated by passengers and crew during their time at sea. The whole process can be described in 4 different stages. The first one is related to separation and collection, where solid waste is typically separated into various categories such as recyclables (paper, cardboard, plastics, glass, metals), food waste, general waste, and potentially hazardous waste (batteries, chemicals, etc.) and then collected by crew members from designated bins placed throughout the ship’s public areas, cabins, and crew spaces.

Then, the storage, once collected, solid waste is stored in designated areas on the ship. These storage areas are often equipped with compactors to reduce the volume of waste and optimize storage space. Different types of waste may be stored separately to facilitate recycling or proper disposal. After the collection, compactors start to compress solid waste, reducing its volume, to help managing the storage of waste on board and may also reduce the frequency of waste disposal when in port.

There are also some special needs to handle of specific waste, according to the typology, usually divided in 3 main categories:

– Recyclables: Items like paper, cardboard, plastics, glass, and metals are typically collected for recycling. They may be compacted and stored separately for offloading in port,

– General Waste: Non-recyclable, non-hazardous waste is stored and compacted for disposal in port or through onboard incineration systems,

– Potentially Hazardous Waste: hazardous materials such as chemicals, batteries, and certain electronic devices are collected separately and stored securely until they can be properly disposed of on land. Items such as chemicals, batteries, fluorescent bulbs, and medical waste are collected separately as hazardous waste. These materials are stored securely and disposed of in accordance with international regulations to prevent environmental contamination.

Finally, when the ship is in port, solid waste is offloaded and disposed of according to local regulations and facilities. Recycling facilities in port may be utilized for recyclable materials, while non-recyclable waste may be sent to landfills or waste-to-energy facilities. Some cruise lines have partnerships with waste management companies to ensure proper disposal of solid waste at port destinations.

Evac Solution

Food Waste

Another important topic about waste, is related to food, due to the big production and consumption on board. Many cruise ships are equipped with food waste treatment systems to manage organic waste on board.

Food waste may undergo processes such as grinding, maceration, or liquefaction to reduce its volume and facilitate handling and disposal. Some ships have anaerobic digestion systems that break down food waste to produce biogas, which can be used as a renewable energy source on board.

Depending on the ship’s itinerary and facilities, food waste disposal methods vary; in some cases, food waste is incinerated on board in waste-to-energy facilities, where it is burned at high temperatures to generate heat and electricity., even if this solution is becoming less and less utilized due the high amount of food needed to be burnt to make the process environmentally sustainable. When in port, food waste may be offloaded for composting, where it can be converted into nutrient-rich soil.

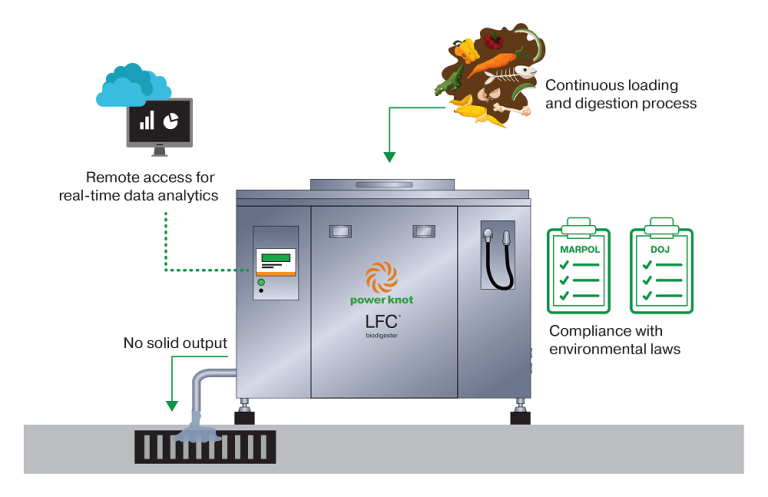

Food waste biodigesters are a groundbreaking step forward in sustainability, enabling ships to tackle food waste in an eco-friendly and efficient manner. These machines act as stainless-steel stomachs that eliminate most food waste within 24 hours. They use a series of processes in which microorganisms break down organic material in the presence of oxygen. The output is grey water that can be sent to the ship’s grey water or black water system.

While this technology has been in use for land applications for over a decade, it has gained remarkable traction in the marine sector. Biodigesters are spearheading the replacement of outdated pulper systems. By strategically placing food waste biodigesters in galleys and garbage rooms, ships can bid farewell to massive pulper tanks, and incinerators allowing them to reclaim valuable deck space. Moreover, biodigesters demonstrate a remarkable capability to process a wider range of waste materials that pulpers cannot, including fish bones, onion skins, shrimp shells, and more. Perhaps most noteworthy is the fact that these biodigesters effectively negate the necessity for waste transportation, thereby drastically reducing costs and streamlining operations.

Other than recycling and disposal, cruise lines often implement measures to reduce food waste generation, such as portion control, menu planning, and encouraging passengers to take only what they can eat. Buffet-style dining areas may have staff members monitoring and managing food waste to minimize overproduction and excess.

Power Knot Waste on Cruise Ships

Wastewater

While flushing toilets, running taps, and shower drains all result in significant amounts of human waste and wastewater, they are not the only forms of sewage that can build up while a cruise ship is on the water. If not stored and dealt with properly, this type of waste can begin to biodegrade, resulting in unpleasant odors and even a buildup of flammable gases.

To overcome this issue, waste is segregated and dehydrated. Wastewater not linked to human waste is known as grey water, undergoes thorough filtration and treatment on board. Sophisticated water treatment facilities, including settlement tanks, various filters, chemical treatments, and water quality tests, ensure that grey water is devoid of harmful contaminants before disposal. Once fully treated, this non-sewage wastewater can be discharged into designated ocean regions. However, stringent regulatory standards must be met before dumping is permitted. The water must be completely clean and pose no serious risk to local marine life and ecosystems.

Human waste, including toilet flush water and water from cabin showers, is referred to as black water. Given its health risks and unpleasant odors, proper handling of sewage is paramount on cruise ships. All forms of human waste undergo rigorous treatment processes in designated areas of the ship inaccessible to passengers. Advanced sewage treatment facilities employ heavy filtration, chemical treatments, and biological composting procedures. Throughout the treatment process, both treated and untreated sewage is stored in airtight holding tanks to control odor. These tanks undergo regular checks for leaks and weak spots to maintain their structural integrity, ensuring the health and safety of everyone on board.

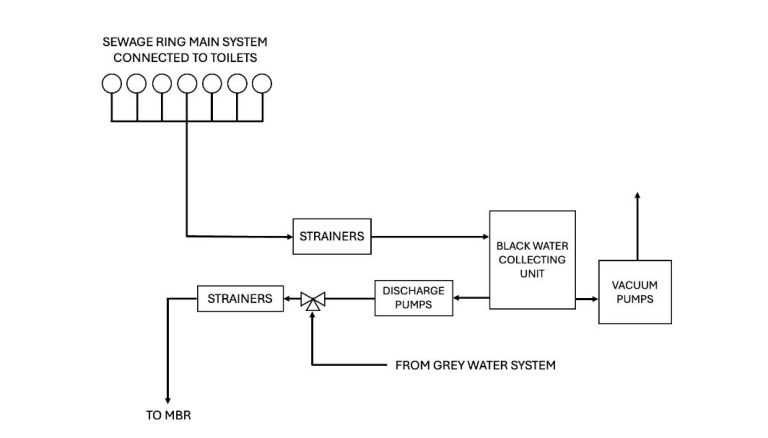

Blackwater is collected in blackwater collecting units via a ring-main system. Depending on the ship’s size, there can be 4-10 collecting units installed throughout technical spaces on board, allowing for easy monitoring and maintenance.

Ring Main System

The blackwater is directed to the collecting tanks either by gravity or vacuum. In vacuum systems, vacuum pumps attached to the tanks generate the necessary vacuum regulated by sensors. Before reaching the collecting units, blackwater passes through coarse strainers to remove large-sized solids that could clog pipework or pumps.

Blackwater collecting units are equipped with discharge pumps, often set on timers or level sensors. These pumps transfer blackwater to screen presses, separating solids like toilet paper, plastics, and rags from the liquid. Screen presses use a mesh screen to separate larger solids, then a screw shaft operated by a motor removes finer suspended solid impurities. Filtered blackwater moves to the treatment stage, while separated solids go to a separate tank, often called a Bio-sludge tank.

Accommodation greywater can be fed to the MBRs (Membrane Bioreactors) along with blackwater. This process is controlled by a 3-way valve, diverting greywater to maintain optimal treatment levels. In the MBR, blackwater undergoes biological treatment and membrane filtration. Aerobic bacteria in the first stage break down sewage, separating sludge from water. The second stage further removes impurities. Inter-Stage Filters (ISFs) remove finer particles before the liquid passes through to the membrane-filtration stage. Sludge is removed daily to prevent clogging and damage to membranes. Treated wastewater is pumped through membrane banks, each with millions of microscopic pores, allowing pure water molecules to pass through while blocking impurities. Chlorine treatment may be used for disinfection before the treated wastewater is pumped overboard. Regular testing ensures the MBR plant’s performance.

EVAC MBR

Galley and laundry greywater have separate storage tanks due to the presence of detergents and oils, which can affect the MBR’s performance. Blackwater management requires strict adherence to maintenance procedures and regular testing. Proper understanding and troubleshooting are essential for continued efficiency and operational continuity. The complexity of the system can pose challenges, particularly on larger ships, necessitating adherence to manufacturer guidelines and regular maintenance schedules to ensure plant health.

In conclusion, waste management on cruise ships encompasses a range of processes, from collecting and treating wastewater to segregating and recycling food waste. By implementing advanced technologies, adhering to strict regulations, and promoting environmental awareness among passengers and crew, cruise lines strive to minimize their impact on the marine environment while providing unforgettable travel experiences. Continued efforts in waste management and sustainability will be essential for the cruise industry to navigate towards an eco-friendlier future.

Don’m miss more updates, news and reviews about the world of cruises on Cruising Journal.