HVAC Systems: climate control on board ships

In contemporary maritime design, the integration of efficient climate control systems is critical to ensuring the comfort and well-being of both passengers and crew.

Mechanical ventilation systems, when combined with air conditioning units, provide comprehensive solutions for heating, cooling, and delivering fresh air to onboard living spaces. These systems not only enhance indoor air quality but also contribute significantly to the vessel’s overall energy efficiency.

For larger spaces, a centralized Heating, Ventilation, and Air Conditioning (HVAC) system is typically employed. The HVAC system plays a pivotal role in cruise ship design and operation, ensuring passenger and crew comfort while maintaining functional efficiency. Given the unique challenges of the maritime environment—including fluctuating weather conditions and the demand for optimized energy management—the HVAC system is indispensable for maintaining a pleasant onboard atmosphere.

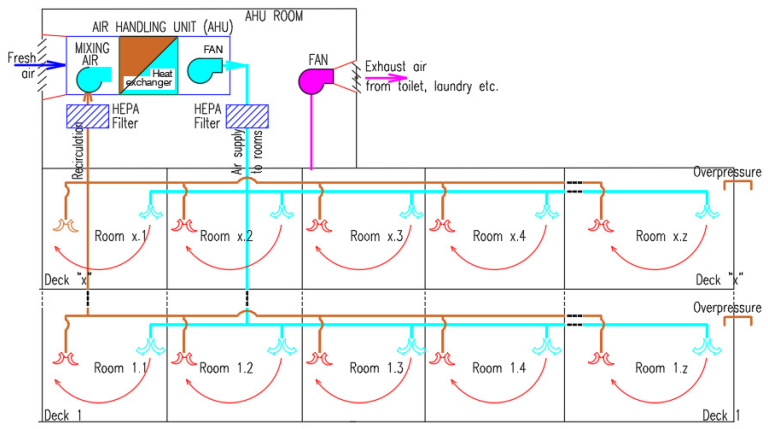

Example of typical arrangement.

At its core, the HVAC system is responsible for regulating temperature, supplying fresh air, and controlling humidity levels, while also ensuring the extraction of stale air. This multi-faceted system is vital for creating and sustaining a comfortable environment across various ship areas, such as passenger cabins, dining venues, lounges, and recreational facilities. By continuously adapting to external weather conditions and internal occupancy changes, the HVAC system ensures optimal comfort and operational efficiency throughout the voyage.

H: Heating is one of the primary functions of the HVAC system. In colder weather, it is vital to provide warmth to various areas of the ship. This heating is often achieved through hot water or steam generated by the ship’s boilers. These boilers utilize fuel oil or other energy sources to create heat, which is then distributed throughout the ship via a network of pipes. By heating water to high temperatures and circulating it through radiators or heat exchangers, the HVAC system effectively warms the air, ensuring that passengers remain comfortable even in chilly conditions.

V: Ventilation is another key aspect of the HVAC system. Proper ventilation is crucial for maintaining good air quality, especially in enclosed spaces where a large number of people gather. The system draws in fresh air from the outside, which is then filtered to remove dust, allergens, and other contaminants. This fresh air is mixed with recirculated air to optimize energy efficiency while still providing a continuous supply of clean air. Exhaust systems are equally important, as they work to remove stale air and prevent the buildup of pollutants, ensuring a healthy environment throughout the ship.

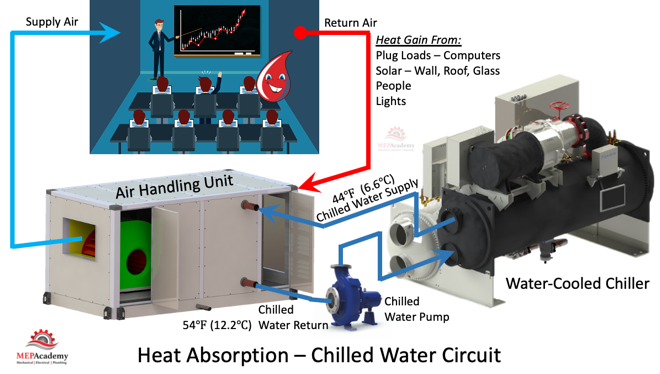

AC: Air conditioning, of course, is the most recognizable function of an HVAC system, particularly in warm climates. The cooling process typically involves the use of chillers, which are machines that employ refrigerants to absorb heat from the ship’s interior and expel it outside. The chillers operate on a cycle that includes evaporation and condensation, allowing the refrigerant to change states and effectively remove heat. This process not only cools the air but also helps to lower humidity levels, creating a more comfortable atmosphere for passengers.

Ventilation and Air Conditioning Systems for Living Spaces

The ventilation and air conditioning systems for accommodation are calculated and designed according to ISO standard 7547. The ventilation and air conditioning system should be designed to ensure the following indoor conditions based on the indicated outdoor air conditions and minimum outdoor air supply of “40% of the total air supplied to the spaces concerned”.

– Summer—temperatures and relative humidity:

Outdoor air +35 °C and 70% RH (Relative humidity)

Indoor air +27 °C and 50% RH (Relative humidity)

– Winter—temperatures

Outdoor air −20 °C

Indoor air +22 °C

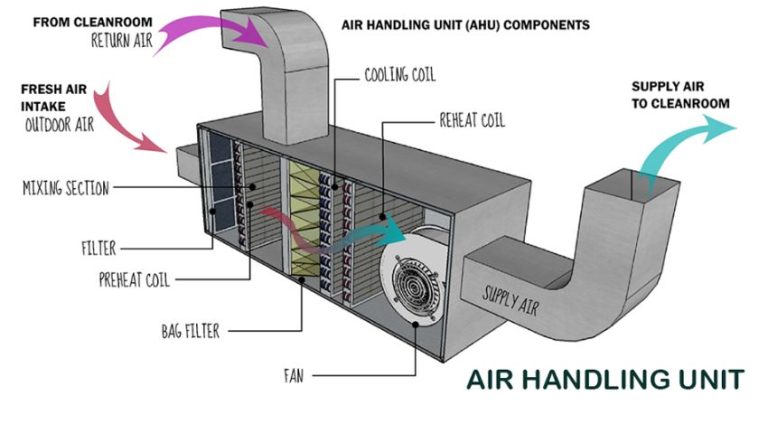

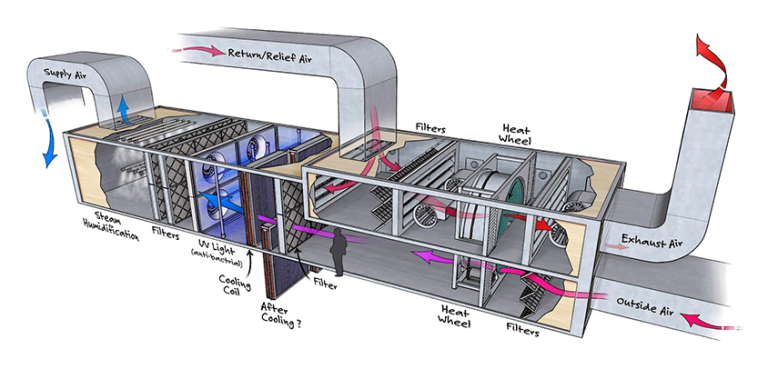

Once the purpose of the HVAC system is established, it’s important to understand how it operates to provide heating, ventilation, and air conditioning throughout the ship. A critical component of the system is the ductwork, which serves as the framework for air distribution. This network of ducts channels conditioned air to various areas on board, ensuring consistent airflow and maintaining uniform temperatures. Proper design of the duct system is essential to minimize resistance and optimize the efficiency of air movement, promoting energy savings and enhanced comfort. The conditioned air is produced and managed by air handling units (AHUs), which play a vital role in filtering, heating, and distributing air across the ship. These units, equipped with powerful fans, are strategically positioned to ensure the effective delivery of air, even to more isolated sections of the ship such as remote cabins or crew quarters.

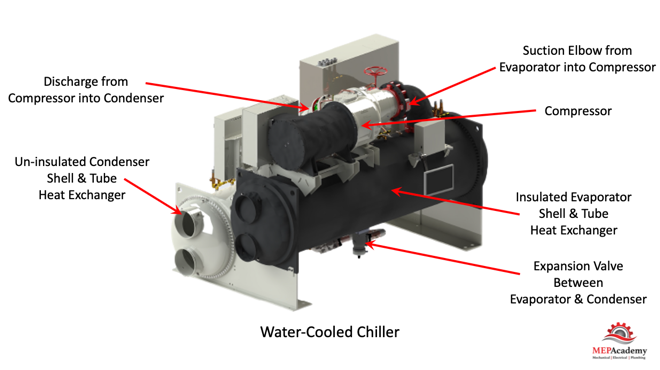

To cool the air, marine chillers generate a cold-water stream that circulates through the system. The AHUs use a cooling coil system to exchange heat between this cold water and the surrounding air, lowering the air’s temperature before it is circulated throughout the vessel. This process, combined with the heating and ventilation functions, ensures optimal climate control for all areas of the ship.

AHU

AHU

AHU

Marine air handling units (AHUs) are essential for heating, cooling, filtering, and circulating air to maintain a comfortable environment for both passengers and crew. These units play a crucial role in sustaining air quality and comfort at sea. The process begins with air intake, where marine AHUs draw in either fresh air from outside or recirculate interior air to enhance energy efficiency. Fresh air intake ensures good air quality, while recirculation minimizes energy consumption. As air enters the AHU, it passes through filters that remove dust, allergens, and other contaminants, ensuring that only clean air is distributed throughout the ship.

After filtration, the air moves to the heating and cooling components. For heating, hot water from the ship’s boilers circulates through coils, warming the air as it passes over them. In cooling mode, a refrigerant absorbs heat from the air, lowering its temperature. This dual-function capability enables the AHUs to adjust to varying climate conditions on board. In addition to temperature regulation, marine AHUs often feature dehumidification, a critical function in humid environments. As the air cools, moisture condenses and is drained away, maintaining comfortable humidity levels and preventing mold growth. Once conditioned, the air is distributed throughout the ship via ductwork, with fans ensuring efficient airflow to all areas.

Chillers

CHILLERS

A marine chiller is a critical component in the heating, ventilation, and air conditioning (HVAC) systems of ships, designed to regulate temperature and ensure a comfortable environment for passengers and crew. Operating in a marine environment presents unique challenges, and chillers play an essential role in addressing these by providing efficient cooling for various onboard spaces. Understanding how a marine chiller works, and its functions reveals its importance in modern maritime operations.

At its core, a marine chiller uses a refrigeration cycle to absorb heat from the ship’s interior and transfer it outside. This process begins with a refrigerant, a specialized fluid that circulates within the chiller. The cycle starts in the evaporator, where the refrigerant is in a low-pressure liquid state. As warm air from the ship’s interior passes over the evaporator coils, the refrigerant absorbs heat and evaporates into a gas. This crucial step lowers the temperature of the air, which is then circulated throughout the ship’s cabins, dining areas, and other spaces. Once the refrigerant has absorbed heat and transformed into a gas, it flows to the compressor. The compressor’s role is to increase the pressure and temperature of the gas, preparing it for the next stage of the cycle. By compressing the gas, the compressor raises its temperature significantly, which is essential for the cooling process. The high-pressure gas then moves to the condenser, where it releases the absorbed heat. In the condenser, the refrigerant passes through coils exposed to outside air or seawater. As the high-pressure gas flows through these coils, it releases its heat to the surrounding environment and condenses back into a liquid state. This heat exchange process is vital for maintaining comfortable temperatures within the ship. Once the refrigerant has returned to a liquid form, it flows back to the evaporator, and the cycle begins anew.

In addition to providing cooling for living and recreational spaces, marine chillers also play a role in other essential systems on board. They are often used for cooling machinery spaces, electronic equipment, and even food storage areas, ensuring that all aspects of the ship function smoothly. Proper cooling helps prevent overheating of critical systems, enhancing overall safety and operational efficiency.

Chillers

CONTROL AND REGULATIONS

Temperature regulation within the HVAC system is achieved through a series of thermostats and control mechanisms that monitor conditions throughout the ship. These controls allow crew members and passengers to set desired temperatures in different areas, making it possible to cater to individual preferences. The ability to manage temperature zones separately enhances the overall comfort on board, as different spaces may have varying occupancy levels and usage patterns. For example, dining areas may require cooler air to accommodate large groups, while private cabins may need warmer settings for comfort.

As said, and part of the AHU job, dehumidification is another essential function of the HVAC system, particularly in humid maritime environments. High humidity levels can lead to discomfort, mold growth, and deterioration of materials on board. The HVAC system employs various methods to reduce moisture levels in the air, including cooling coils that condense moisture and remove it from the air. This process is vital for maintaining a healthy indoor climate and protecting the integrity of the ship’s infrastructure and furnishings.

Marine AHUs are equipped with advanced control systems that allow for precise management of temperature, humidity, and air quality. Sensors continuously monitor conditions in real-time, enabling the system to make automatic adjustments based on occupancy levels and external weather fluctuations. Operators can set specific parameters for different zones of the ship, allowing for personalized comfort tailored to the needs of passengers and crew.

RELIABILITY, ENERGY AND EFFICIENCY

Marine chillers, essential for maintaining comfortable conditions in warmer climates, are also designed for maximum efficiency and reliability. Many ships use multiple chillers to ensure redundancy—if one unit fails, others seamlessly take over, preventing any interruption in air conditioning. This not only safeguards comfort but also enhances system resilience. Additionally, modern chillers feature advanced control systems that allow for precise temperature regulation. These systems continuously monitor real-time data, such as temperature fluctuations and occupancy levels, adjusting cooling output accordingly. This adaptability ensures that energy is used efficiently, further reducing operational costs and environmental impact.

Energy efficiency is, in fact, a critical factor in the design and operation of HVAC systems on cruise ships, where advanced technologies help reduce energy consumption while maintaining passenger comfort. Modern marine air handling units (AHUs) incorporate features like variable-speed fans and heat recovery systems, optimizing airflow and minimizing energy waste. These innovations allow HVAC systems to deliver high performance while significantly lowering energy use, contributing to the ship’s overall sustainability. By implementing these energy-saving innovations, cruise ships can achieve both environmental sustainability and significant cost reductions, making energy efficiency a central component of modern maritime HVAC design.

AHU + Chillers

SAFETY

Safety is paramount in all aspects of cruise ship operations, and the HVAC system is no exception. Regular maintenance is crucial to ensure that the system functions efficiently and safely. Crew members are trained to identify and address issues such as leaks or blockages that could compromise the system’s effectiveness. Moreover, emergency protocols are in place to maintain HVAC functionality during critical situations, such as power outages or fire emergencies. This ensures that passengers and crew remain safe and comfortable, even in challenging circumstances.

CONCLUSION

In conclusion, the HVAC system on a cruise ship is a sophisticated, integrated network that plays a vital role in creating a comfortable and healthy environment for all on board. Through its combined functions of heating, ventilation, and air conditioning, the system adapts to varying conditions, providing personalized comfort while maintaining air quality. The advanced technologies and engineering practices employed in modern cruise ship HVAC systems demonstrate a commitment to passenger satisfaction, energy efficiency, and safety. As cruise ships continue to evolve, the importance of effective HVAC systems will remain a cornerstone of the cruise experience, ensuring that guests can enjoy their voyages in comfort, regardless of the weather or sea conditions.

Don’t miss updates, news and reviews about the world of cruises on Cruising Journal with photos, videos and cruises on offers.